Under the “Day in the Life” experience program

with our partner Atlassian Williams Racing,

two employees were chosen to take part in the exchange program for the Japan Grand Prix 2025.

Prior to the race, they visited the Atlassian Williams Racing HQ in Grove, U.K.,

where they talked in-depth with Formula One technicians

and got hands-on with their cutting-edge technology.

By bringing skills and ideas together, these encounters will empower

the creation of value like never before.

Under the “Day in the Life” experience program

with our partner Atlassian Williams Racing,

two employees were chosen to take part in the

exchange program for the Japan Grand Prix 2025.

Prior to the race, they visited the Atlassian Williams

Racing HQ in Grove, U.K.,where they talked in-depth

with Formula One technicians and got hands-on

with their cutting-edge technology.

By bringing skills and ideas together, these encounters

will empower the creation of value like never before.

Engaged in R&D for sound-driven engine inspection

apps since joining Komatsu.

Currently Uehara is a software engineer in charge

of analysis of voice data using audio apps.

Assigned to the Quality Assurance Department since

joining Komatsu. In addition to involvement in the launch

of new models of hydraulic excavators, bulldozers models

and other machines, Shuto’s responsibilities as a quality

assurance engineer include improving workplace QA,

responding to customer feedback, and diverse activities to

assure stable manufacturing and improvement of quality.

Our “Day in the Life” exchange program in partnership with Atlassian Williams Racing is enabling Komatsu employees to be a part of Formula One Grand Prix events around the world. Through this initiative, employees have an opportunity to experience the highest standards of technology, safety, and advanced engineering in motorsports.

Previously traveled the world as the team’s No.2

mechanic. Currently his responsibility is testing, verifying

and approving hydraulic components and entire systems

as a hydraulic technician.

Veteran technician with almost 35 years of experience

including gearbox development work and as a race team

technician at numerous events. Currently he serves as the

Heritage Car Build Manager.

At the Centre, visitors not only gain a deeper understanding of the history and cutting-edge technology of Atlassian Williams Racing, but also can virtually experience e-sports, relive the glory and unforgettable moments of the past, get a peek behind the scenes of exciting races, and check out exhibits of historic memorabilia and priceless artefacts.

Engaged in R&D for sound-driven engine

inspection apps since joining Komatsu.

Currently Uehara is a software engineer in charge

of analysis of voice data using audio apps.

Assigned to the Quality Assurance Department

since joining Komatsu. In addition to involvement

in the launch of new models of hydraulic

excavators, bulldozers models and other

machines, Shuto’s responsibilities as a quality

assurance engineer include improving workplace

QA, responding to customer feedback, and

diverse activities to assure stable manufacturing

and improvement of quality.

Our “Day in the Life” exchange program in partnership with Atlassian Williams Racing is enabling Komatsu employees to be a part of Formula One Grand Prix events around the world. Through this initiative, employees have an opportunity to experience the highest standards of technology, safety, and advanced engineering in motorsports.

Previously traveled the world as the team’s No.2

mechanic. Currently his responsibility is testing,

verifying and approving hydraulic components

and entire systems as a hydraulic technician.

Veteran technician with almost 35 years of

experience including gearbox development work

and as a race team technician at numerous

events. Currently he serves as the Heritage Car

Build Manager.

At the Centre, visitors not only gain a deeper understanding of the history and cutting-edge technology of Atlassian Williams Racing, but also can virtually experience e-sports, relive the glory and unforgettable moments of the past, get a peek behind the scenes of exciting races, and check out exhibits of historic memorabilia and priceless artefacts.

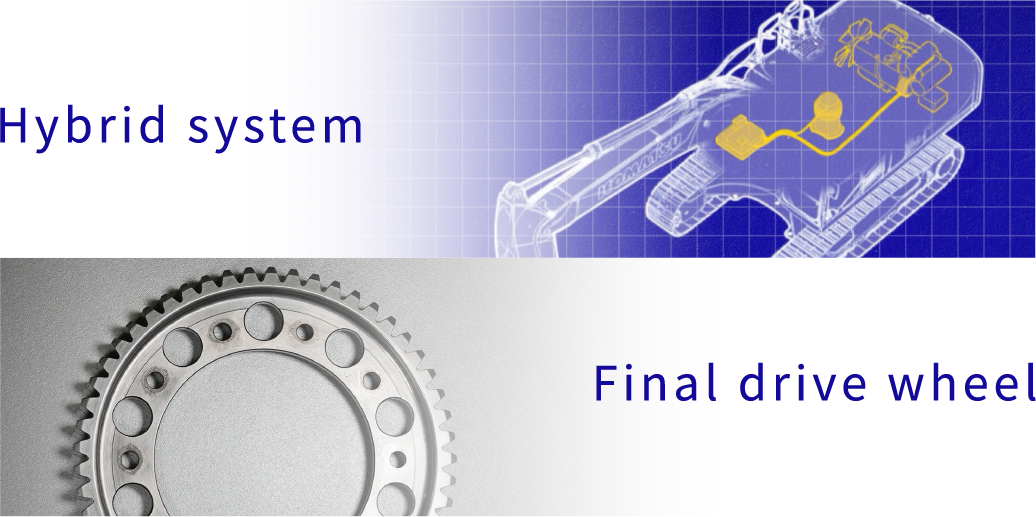

Atlassian Williams Racing's FW47 machine and Komatsu's HB365LC-3 hybrid excavator.

At first glance, these two machines seem to exist in completely different worlds,

but a deeper look reveals that they have a lot in common technically,

such as hybrid systems.

And the final drive wheel shown here is a historic cornerstone of our ever-stronger partnership.

Atlassian Williams Racing's FW47 machine and

Komatsu's HB365LC-3 hybrid excavator.

At first glance, these two machines seem to exist

in completely different worlds,

but a deeper look reveals that they have a lot in

common technically,such as hybrid systems.

And the final drive wheel shown here is a historic

cornerstone of our ever-stronger partnership.