Engaged in R&D for sound-driven

engine inspection apps since joining

Komatsu. Currently Uehara is

a software engineer in charge

of analysis of voice data

using audio apps.

Engaged in R&D for sound-driven engine

inspection apps since joining Komatsu.

Currently Uehara is a software engineer in charge

of analysis of voice data using audio apps.

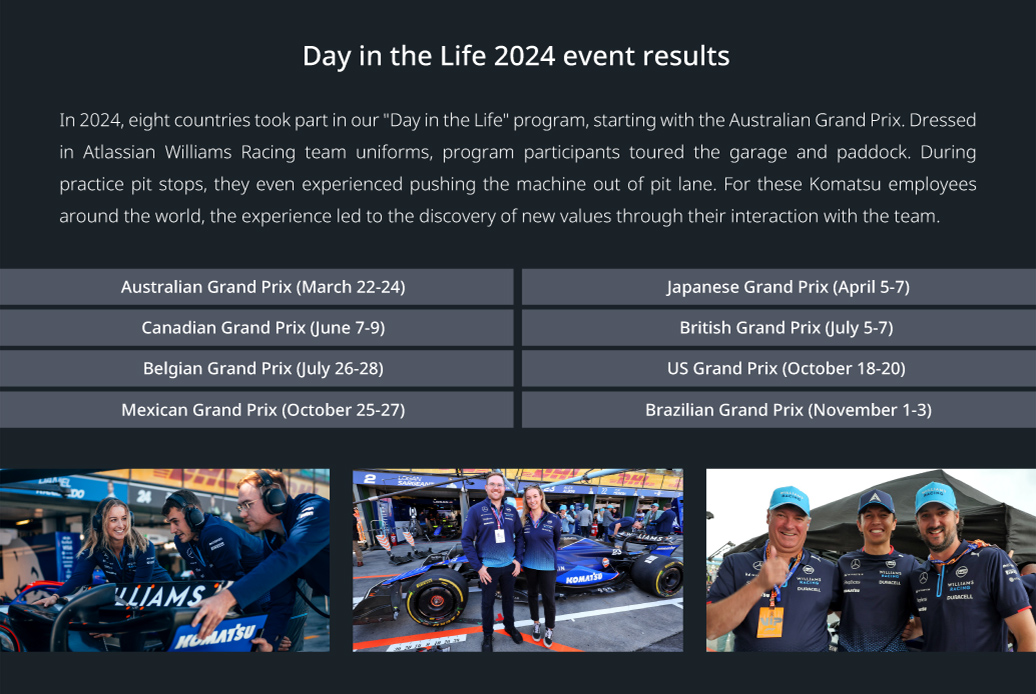

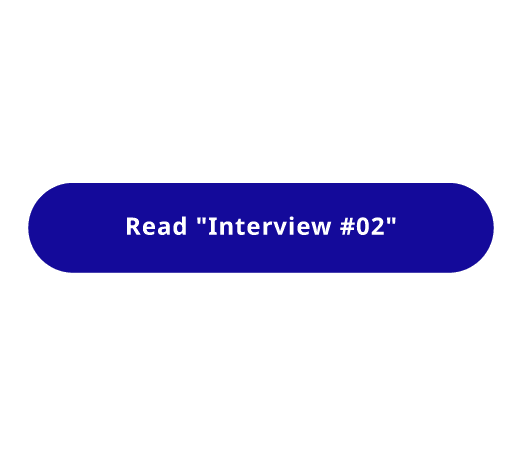

I was both deeply impacted and nervous about the huge responsibility of being one of only two people in Japan to participate in this project this year. By experiencing a workplace that demands the highest standards of speed and precision, I expected to learn much about the importance of teamwork. I especially wanted to know how they optimize the decision-making process and keep the awareness of each member at such a high level. What I learned will be useful for more effective team management in Komatsu's projects. I saw how our experience as members of a team can help each of us to both better recognize our own individual role and reaffirm a commitment to work together for the success of the whole team. That was my first impression.

When you ask the technicians at Atlassian Williams Racing a question, you get an immediate and precise answer. The depth of their knowledge and expertise was amazing. At the same time, I could sense their determination to grasp every detail of their job so completely that they could explain it to someone else. That is a quality to be learned. As a technician myself, I could relate with these guys in many ways. Also, their always cheerful and positive attitude was impressive. Frankly it was wonderful to see the whole team working as one towards their goals. They do their work not only with professionalism, but also with warm humanity. That too is something to be admired.

Development of construction machinery and Formula One cars have much in common. Both aim to improve efficiency and performance using the latest technology. Both machines must perform under extreme conditions. And in the case of both, consideration for the global environment has led to the development of hybrid technology. When I visited the headquarters of Atlassian Williams Racing, I was surprised at the speed of development. Everywhere is meticulously managed to create a workplace environment where all can work efficiently. I was also impressed by the pride the engineers take in their work and their dedication to see the job all the way to the end. No matter the difficulty, they never give up, and complete each job, always aware of their responsibility. They seem to pursue innovation and take on challenges without fear of failure. This attitude resonates with our own Komatsu value of “taking on challenges.

Assigned to the Quality Assurance

Department since joining Komatsu.

In addition to involvement in the

launch of new models of hydraulic

excavators, bulldozers and other

machines, Shuto’s responsibilities as

a quality assurance engineer include

improving workplace QA, responding

to customer feedback, and diverse

activities to assure stable

manufacturing and improvement of

quality.

Assigned to the Quality Assurance Department

since joining Komatsu.

In addition to involvement in the launch of new

models of hydraulic excavators, bulldozers and

other machines, Shuto’s responsibilities as a

quality assurance engineer include improving

workplace QA, responding to customer feedback,

and diverse activities to assure stable

manufacturing and improvement of quality.

When I was selected, I felt honored to have this opportunity to interact directly with the engineers at Atlassian Williams Racing. I feel that Formula One is more than just racing. It is the cutting edge of vehicle development and engineering. There are engineers around the world who have very high levels of technical skills and are innovative. One of my goals has been to exchange ideas with them and get new ideas. That’s why I was very excited about this opportunity. Although the development of construction machinery and Formula One technology may differ in many ways, both fields require highly advanced technology. During this experience, I wanted to discover what we have in common while learning new approaches to promote innovation, and to bring what I learned back to Komatsu.

While they are clearly dedicated as technicians at Atlassian Williams Racing, you can also feel their passion as fans of Formula One. The frequent regulation changes mean that all must always work at peak performance and together to advance development. I was impressed by this attitude, and how their speed and unity supports the team. I was also surprised to learn that they developed a new machine in only about six months while constantly tackling new challenges to make the car even faster. I think this attitude has a positive impact on the entire team.

During my visit to Atlassian Williams Racing headquarters, I was struck by their “power of teamwork.” It is a capability I want to harness more effectively in my own work at Komatsu in the future. Close collaboration between different departments and engineers and working together toward a common goal is essential for any project. By enriching communication between departments, we can produce even greater results. Using my perspective as an engineer and what I’ve learned about the power of teamwork from Atlassian Williams Racing, I aim to advance our technological innovation and our Komatsu’s leadership in the industry.

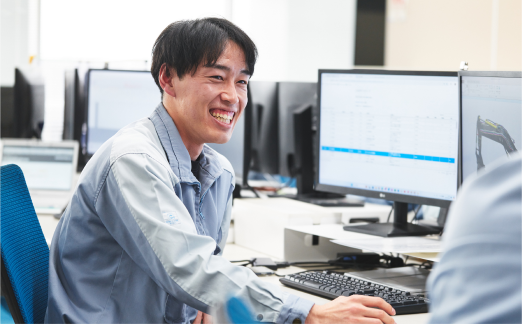

From April 4 to 6, Atlassian Williams Racing participated in the Japanese Grand Prix at Suzuka Circuit.

On the first day, Practice 1 and 2 sessions were held.

The practice 3 session was followed by the Official Qualifying Session on the second day. The third day was Race Day.

Our two young Komatsu engineers participated in the Practice Session on the first day as part of the pit crew.

Our report shares scenes and impressions of the heated battle at Suzuka.

From April 4 to 6, Atlassian Williams Racing

participated in the Japanese Grand Prix

at Suzuka Circuit. On the first day,

Practice 1 and 2 sessions were held.

The practice 3 session was followed by the Official

Qualifying Session on the second day.

The third day was Race Day. Our two young

Komatsu engineers participated in the Practice

Session on the first day as part of the pit crew.

Our report shares scenes and impressions of the

heated battle at Suzuka.

After my visit to Grove*, I was really looking forward to the race. I still remember how tense I felt when I put on the Atlassian Williams Racing uniform. During pit stop practice, we actually pushed the car out of pit lane. I was amazed at how light and easy it was to push.

On race day, I witnessed with my own eyes how tough race conditions are and the risks that drivers were taking. I was awed by the incredible speed of the cars. Despite all that, all the team members were calm and cheerful. It was clear that they had built a deep relationship of trust with each other.

*Grove, U.K., the home of Atlassian Williams Racing.

First of all, I was astonished by the sheer scale of this Formula One event. Over the three days, estimated total attendance at the Japanese Grand Prix reached 260,000. The excitement reached its peak on race day when 20 cars started their engines. The powerful roar of the engines shakes the very air. It is beyond imagination. Seeing the cars racing at speeds over 300km/h was breathtaking. I couldn’t help but think about the high level of skills of the drivers and technicians that made it all possible. Carlos’ result was really unfortunate, but I was very happy for Alex whose performance earned points. I got both drivers’ autographs on my team hat.