May 09, 2025

Komatsu Ltd. (hereinafter “Komatsu”) (President and CEO: Takuya Imayoshi) will begin trial introduction (hereinafter, “the trial”) of forestry machines manufactured by its wholly owned subsidiary, Komatsu Forest AB (Headquarters: Umeå, Sweden; CEO: Jens Bengtsson, hereinafter, “Komatsu Forest”) at customer job sites in Japan, starting in May 2025. The trial will assess the effectiveness of the Cut-to-Length (CTL) method* in Japanese forestry operations, with the aim of the broader introduction of harvesters and forwarders adapted for CTL, into the Japanese market in the future.

*Cut-to-Length (CTL) method: A common forestry method in Europe, involving felling standing trees, delimbing, and bucking them into logs of specified lengths in the forest, using two types of machines—a harvester for felling and processing, and a forwarder for transporting the logs.

[Komatsu 931XC harvester]

Komatsu is enhancing its forestry machinery business, a circular business that supports forest regeneration. Strengthening this business as the company’s third core pillar, following its construction and mining equipment businesses, Komatsu has expanded globally by promoting mechanization in harvesting, processing, forwarding, and planting operations, as well as the provision of fleet management and timber handling solutions. In Europe, Komatsu’s extensive lineup of products and solutions, tailored for the CTL method, has been highly praised by customers.

[Komatsu 855 forwarder]

Japan boasts an expansive forested area, comparable to the Nordic forestry nations, and holds strong potential for timber production. However, excavator-based machines have long been mainstream in Japan, and multi-machine processes have been the norm. Because of the country’s steep terrains, wheeled forestry machines made overseas were traditionally considered unsuitable. Nonetheless, amid labor shortages and a declining forestry workforce, there is growing interest in more mechanized approaches. The CTL method enables the completion of all timber production processes with fewer machines and fewer operators, offering potential improvements in productivity, safety, and cost efficiency, compared to conventional Japanese practices.

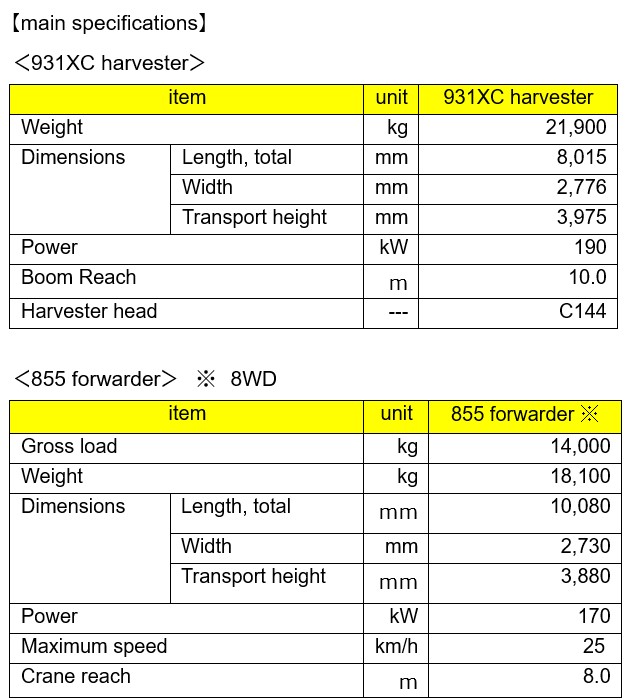

The trial will involve the Komatsu 931XC harvester (operating weight: 21.9 tons) and the Komatsu 855 forwarder (maximum load capacity: 14 tons). The trial will commence in May 2025 at customer job sites across Hokkaido, Honshu, and Kyushu, and will continue for approximately one year. Some regions will also include comparative studies with traditional methods. In addition, Komatsu plans to evaluate ICT-based forestry solutions by combining machine data—such as GPS location, production planning, and results—with forest stand distribution information to optimize routing during harvesting and forwarding, aiming to further improve productivity through efficient operation management.

The first Test, starting in May, will be conducted jointly with Mitsui Bussan Forest Co., Ltd. (President and CEO: Yasunori Jinno) on forests owned by Mitsui & Co., Ltd. in Hokkaido.

By leveraging the expertise and technology cultivated in Europe, Komatsu will continue to contribute to solving customer challenges in the Japanese forestry sector by demonstrating the effectiveness of the CTL method.

No : 0018(3334)

Corporate Communications Department

Sustainability Promotion Division

Komatsu Ltd.

tel: +81-(0)3-6849-9703

mail: JP00MB_cc_department@global.komatsu

*The information may be subject to change without notice.